That's basically how cooling systems have worked for a long time since Fords Thermo Syphon System

This post is from our friends over at BimmerWorld, experts in all things BMW since 1997. Like this story? Find more just like it at their blog.

Internal combustion engines rely on a cooling system to regulate the engine temperature as well as provide heat for the climate control system (HVAC) and the mechanics of it hasn't changed in 120-odd years. BMW systems are not much different than any other car but we created this page to educate all BMW owners on how the system works and address specific problem areas unique to BMWs that any owner should be aware of.

Over time, cooling systems have become more sophisticated and complex but the core components haven't really changed:

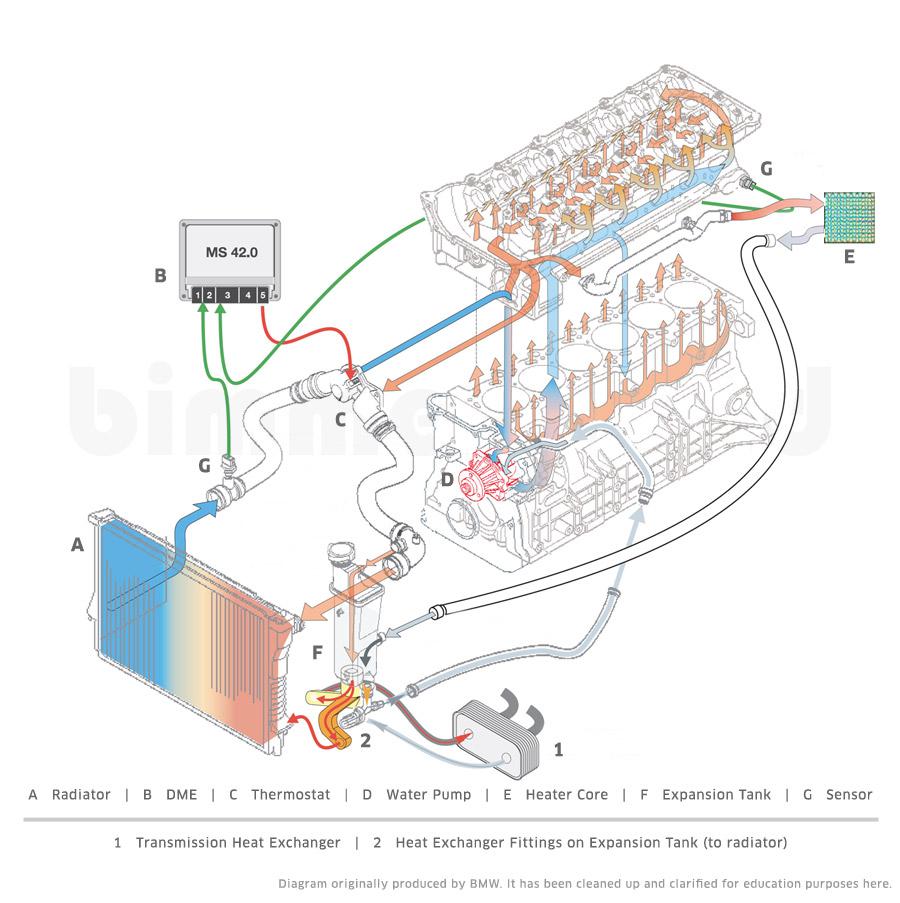

In essence, the cooling system uses a robust anti-boil/anti-freeze chemical mix that absorbs heat in the engine, circulates the heated fluid to the radiator for cooling, and then runs the cooled fluid back through the engine. Additional sub-systems like the heater core, turbochargers, and oil coolers are tied in with the main engine cooling system or have their own dedicated sub-systems.

The engine, hoses, radiator, and expansion tank are filled with coolant mixture. On a BMW this is a mix of monoethylene glycol and distilled water. The water pump circulates the coolant and keeps the system pressurized.

Starting from the pump, coolant enters the engine block and cylinder head to regulate internal temperatures. When hot coolant leaves the engine block it is split into two directions: to the thermostat or to the heater core to heat your interior.

Flow through the radiator is controlled by the thermostat. Depending on coolant temp, the thermostat will be either closed or partially open. When closed coolant flow through the radiator is stopped and hot coolant will flow from the engine block to the thermostat and back through the water pump where it will re-enter the engine.

When the thermostat is open, radiator flow resumes and cooled coolant enters the thermostat, mixes with the hot coolant, and then continues onto the water pump. Once the coolant temp is lowered the thermostat closes again.

The expansion tank holds overflow and extra fluid to be used to supplement fluid being used elsewhere, such as for the heater core or for an oil cooler.

Older models have two phases of operation: warm-up and regular. During the warm-up phase the thermostat is closed, which allows coolant to circulate through the engine again and bring the engine up to operating temp sooner. Once in regular mode the thermostat will open partially to regulate coolant temp.

More modern BMWs have a plethora of operating modes to meet various cooling goals. They use sophisticated electronics to control the operation of the thermostat and water pump to oversee internal engine and accessory temps.

Few vehicle systems will leave you stranded on the side of the road but the cooling system is certainly near the top of the list.

Regular and preventative maintenance is crucial. Cooling systems break down and fail when regular service is ignored, regardless of the materials or quality of components. There is almost always a tell-tale sign of impending cooling system failure so do yourself a favor and address any warning signs ASAP.

This page is laid out by component rather than by car because the same principles apply regardless of year or generation. We have identified any problem areas below as well.

BMW prefers a specific coolant blend for all of their cars that is compatible with the extensive use of aluminum, magnesium, and plastic found in BMW engines.

BMW recommends the coolant be mixed with distilled water. Why do they insist on distilled water? The water goes through multimedia particulate and charcoal filters and is then distilled. The water is vaporized into pure water and then bottled. All other minerals are left behind. This avoids any contamination that might occur with the additives and chemicals from regular tap water.

BMW recommends a mix of 50:50 but this can vary depending on temperature requirements. Note that many racing organizations do not allow coolant at all because spills or leaks on the track are difficult and time consuming to clean up and large coolant spills are slippery.

Coolant also has the job of lubricating the water pump. If you feel coolant between your fingers it has a lubricity to it. This gives the moving parts of the water pump some lubrication that straight water will not.

The BMW coolant is light blue in color.

There are few brands for the correct BMW coolant. We offer the Genuine BMW as well as a few other OEM-types. The Genuine is the most popular even though some others offer a higher boiling point than Original BMW. Most race series ban the use of coolant because it can make a slippery mess when spilled so we tend to use Genuine coolant or straight water with Red Line Water Wetter.

Water Wetter is a non-glycol lubricant and corrosion inhibitor that is allowed in most racing series. It's also specifically designed to reduce cylinder head temperatures and reduce the potential for knock/pinging due to high temps.

The water pump is centrally located in the engine and is either mechanical or electric, depending on the generation. Nearly all BMWs from 2006-2018 use an electric pump.

Previous to 2006 and many post-2018 are belt-driven pumps. More on this in a minute.

The pump works like a water mill - the blades of the pump (impeller) scoop up coolant and push it through the system. Most pumps are located at the front center of the engine with direct access to the engine block and cylinder head. A hose connects it to the thermostat. Mechanical pumps are working all the time while electrical pumps were programmed to work only when needed, determined by logic built in to the engine computer.

Overall, BMW water pumps have been quite reliable with a few infamous exceptions:

This mechanical pump used plastic for its spinning impeller for the first time. The plastic blades would break apart, leaving nothing to scoop up the coolant. The failure happened without warning and left quite a few people stranded. BMW moved quickly by reverting to a metal impeller pump while they figured out the plastics issue. By 1998 they had re-released the pump with a composite impeller that has been ultra-reliable ever since. Some people prefer the reassurance of a metal impeller and the aftermarket continues to offer it (but unnecessary as far as we're concerned). A Stewart Components performance water pump is also available with more flow and stainless steel materials.

This was BMW's first electric water pump. Switching to electric offered many advantages - less wear and tear on belts, simplified the belt and pulley system, better fuel economy due to less parasitic drag, and cooling could come under electronic control. The pump is mounted on the side of the engine block. The problem with this electric design is that the internal electrical components fail without any warning. Ironically, one compelling theory is they fail due to heat! There is no fix other than total replacement of the pump. If someone could come up with an improved circuit board or make it serviceable they would make a small fortune. It's this unresolved failure that ruined an otherwise innovative design upgrade. If your electric water pump has more than 60,000 miles you're on borrowed time and a failure could happen at any moment.

The sudden failures of electric water pumps, with no clear explanation, and lack of a long-term permanent resolution seems to have led BMW to abandon electric pumps for some 2019-on new models.

The latest G20 3-series and B58TU engine have reverted to a mechanical water pump paired with a Heat Management Module with extensive cooling responsibilities.

The thermostat regulates the temperature of the coolant - allowing hot coolant to circulate or mixing in some cooled coolant to lower the overall temperature, depending on need. When the engine is cold, or you turn your heater on, the thermostat will be closed, forcing the coolant to circulate back through the hot engine. When the coolant gets to a certain hot temperature the thermostat will open and coolant from the radiator is allowed to enter the system. Keeping the thermostat closed will help the engine heat up faster (reducing emissions or improving performance) while having a open thermostat will lead to engine temperatures being too low.

Older thermostats were unbelievable simple: a spring-loaded diaphragm sealed against a metal ring with wax. As temps and pressures rise the diaphragm will open against the wax seal and coolant would flow. Later thermostats are electrically controlled to better manage engine temp. Don't think of the thermostat as one single door, either open or closed. It's more like cars merging on a highway. With no new cars traffic moves freely and quickly (hot coolant). On-ramps allow new cars to enter the highway which slows the speeds down (cooled coolant). This analogy works better if there is a stoplight on the on ramp.

In many cases the thermostat is located in close proximity to the water pump so changing one usually means changing both.

The radiator (and its shell) used to be the most recognizable styling feature on a car because it sat front and center to maximize surface area to air flow. Even though the radiator is now tucked within the bodywork and all but invisible its principles of operation remain unchanged. Even though there is some "radiant" heat the radiator uses convection cooling - hot coolant comes in one end, is passed through tiny tubes in the core that are exposed to air flow, and cooled fluid exits out the other end. On later models (2006+) the car can have multiple radiators supporting different systems and cooling demands. For example, the transmission oil may be cooled by a dedicated radiator.

Most BMW radiators use an aluminum core with tiny tubes for coolant flow. Aluminum strips, also known as fins, are then woven between each tube to direct air flow. All factory BMW radiators are known as single-pass designs - the fluid moves from one side to the other. More advanced designs use a triple-pass layout where coolant criss-crosses the core for longer exposure to cooling air. Radiator cores themselves are quite robust and rarely the source of cooling problems unless damaged by debris or wear and tear after high mileage.

BMW radiator problems usually stem from the plastic used for the end tanks and hose connections. Over time and with exposure these tanks will develop cracks and leaks. It may take several years but it's only a matter of time before this plastic fails. Depending on your needs you can replace it with another OEM-type plastic design or upgrade to an all-aluminum design. Note that OEM radiators will perform just like the original and with the same expectations of performance and longevity. High priced aluminum radiators are typically better and go through extensive testing and quality control. However, cheap aluminum may be inferior and leave you with more regrets than benefits. When it comes to aftermarket parts, you get what you pay for.

It's important to note the differences between a radiator and a heat exchanger. They both have similar jobs and sometimes are interchanged in conversation. The radiator uses convection cooling by air flow to cool the fluid mixture (water:air). The heat exchanger uses fluid to cool something else (usually intake air or oil) and is dependent on a radiator to supply the cooling fluid. There are two common applications of heat exchangers in BMWs: oil cooling and intake air cooling.

Oil heat exchangers have taken the place of traditional air:oil coolers and are used for engine or transmission oil cooling on a number of models. They are more compact and can be located anywhere in the engine bay as they don't need to be in the air flow. They only need a supply of cooling fluid from an existing radiator and an array of hoses for the coolant and the oil.

The 2017+ B46 4-cylinder and B58 6-cylinder engines have a heat exchanger integrated inside the intake manifold. Instead of there being an open cavity and plenums inside the manifold, there's a small water:air cooler. This is the ideal place to cool the incoming air before it enters the cylinder head. The placement of the heat exchanger saves space as it doesn't require a large front mount intercooler and associated piping. The cooling fluid supply can come from an existing radiator but requires a small auxiliary water pump to provide the flow. Mounting the heat exchanger on top of the intake adds a lot of weight above the center of gravity but is necessary for the B46/B58's engine layout.

A radiator is only effective at convective cooling when the car is in motion. This airflow over the tubes is the only way the radiator can cool the fluid. That's why all street cars have a fan to provide auxiliary air flow. Older cars have the fan mounted on the water pump shaft and the fan spins all the time. Later cars (around 1999) have a fully electric fan that is triggered by coolant temperature. Once the coolant reaches a certain temperature the fan turns on. An extra threshold might be built in to engage a faster speed. The electric fans are superior especially in heavy traffic where speeds and air flow are low.

Intelligent heat management also applies to newer models with electric water pumps and more sophisticated electronics. The logic built into the engine computer can turn the water pump on or off, depending on the need. Engine temperature is directly related to vehicle efficiency so it may be advantageous to have the engine run hotter than "normal". In that case it doesn't make sense to have a water pump that is engaged all the time. Conversely, the electric pump can also be used to cool and circulate fluid after the engine has turned off. This is especially critical on turbochargers and the BMW systems will circulate coolant through them after shut down. There are also smaller auxiliary water pumps on some models that do the same thing for various systems.

The expansion tank is also known as the overflow tank or coolant reservoir. As cooling demands change the level of coolant in this tank will go up or down. It's also a place where coolant can spill into when system pressure is too high. The cap on the tank serves a vital purpose of venting/controlling system pressure. Too much pressure needs to be vented to prevent a failure. Too little pressure leads to poor system performance. For this reason the expansion tank, cap, and bleed valve are the highest points of the cooling system.

The expansion tank on 1992+ models seems to be the most common source of leaks and broken plastic. It must be a material issue or quality control problem that allows the plastic to split or warp and cause leaks. Failures are not an epidemic and they typically last 5-6 years so maybe that's just their expected demise. Unless the car is tracked or raced, most people simply reinstall an OEM plastic tank with the expectation that it will fail and need replacement again in the future. For ultimate reliability, but higher cost, we offer an aluminum expansion tank for some models.

Hoses and connections have evolved from slip fit with a hose clamp to positive-locking types with solid fittings. It used to be common to replace hoses because of a leak or deformed hose. But now the fittings and tolerances between hard parts is so close that leaks are rare. The only time it makes sense is if the quick-disconnect has been used repeatedly and the latch mechanism can no longer provide enough clamping power to secure the hose. Often times you can fix a leak simply by replacing the rubber o-ring seal inside the connector.

Cars are not getting any simpler and its the cooling systems that have had to do more with less. Cars have become more aerodynamic, taking frontal area away from the radiator space. More parts and systems are jammed under the hood which traps heat. Turbochargers generate more heat under the hood too and also require their own cooling and oiling systems. Oil coolers are either air- or water-cooled. Even electronics get their own cooling fans. Below we will briefly detail the various sub-systems that require or receive cooling resources.

Nearly all BMW automatic transmissions, and some manuals, get their oil cooled with the help of the engine coolant mix. In most cases there is a heat exchanger that circulates cool fluid around a chamber of transmission oil. The oil is carried to and returned from the heat exchanger by rubber hoses. Coolant is also carried by a different set of hoses, usually from the radiator.

Most M models and some factory performance options include an engine oil cooler. In older models it's a simple radiator design using oil:air convection. But in other models coolant is used with a heat exchanger, similar to the transmission oil system above.

The first great wave of factory BMW turbo models appeared in 2007 with the N54 135i/335i/535i. By using exhaust gases (which are already super hot), and then compressing intake air (which turns it hot), a cooling solution is needed on each turbo. BMW turbos get their oil and coolant supply from the engine block through dedicated lines. Cooling demands are managed by the engine computer which will continue pumping coolant through the block and turbos even if the engine is off.

You can't say BMW doesn't take performance seriously. If your car comes with the right combination of options you got additional radiators and an auxiliary water pump, just for additional cooling performance. Options like the M Performance Package or M Sport package added coolant radiators in the nose for added surface area and cooling. The M Sport models feature ///M-inspired front spoilers with additional openings just for radiators. It's the perfect example of how important cooling is on these modern BMWs.

With a few exceptions BMW cooling systems are reliable and up to the task of providing adequate cooling for daily driving. Upgrades exist, mostly to get away from the problematic plastic pieces. Making the cooling system more robust and bulletproof does no harm even if it may be excessive for daily street use. However, aluminum expansion tanks and radiators exist for a reason and that's to address the shortcomings of the original design. In the end your only regret is that you spent too much.

For BimmerWorld, better cooling became a necessity on our F30 328i race cars built for endurance racing in the IMSA Continental Sports Car Challenge. We found that even with the stock turbo it was sustained high temperatures that killed our performance. We petitioned for a bigger turbo on the grounds that the larger turbo was less-stressed and could put out the same power with lower temps but were denied. That required us to really attack the cooling system on the F30 to make it more efficient for hours of continuous racing.

BMW Cooling System with Mechanical Water Pump and no transmission cooling

BMW Cooling System with Mechanical Water Pump with transmission cooling

BMW Cooling System with Electric Water Pump and Manual Transmission

BMW Cooling System with Electric Water Pump for Automatic Transmission

BMW Turbo Cooling System with Electric Water Pump and Manual Transmission

So....plastic in critical areas, in addition to finicky electronics. This is why they are problematic. Got it.

More modern BMWs have a plethora of operating modes to meet various cooling goals. They use sophisticated electronics to control the operation of the thermostat and water pump to oversee internal engine and accessory temps.

aircooled said:More modern BMWs have a plethora of operating modes to meet various cooling goals. They use sophisticated electronics to control the operation of the thermostat and water pump to oversee internal engine and accessory temps.

The essentially means speeding up the electric water pump.

That doesn't really explain all the failures.

z31maniac said:aircooled said:More modern BMWs have a plethora of operating modes to meet various cooling goals. They use sophisticated electronics to control the operation of the thermostat and water pump to oversee internal engine and accessory temps.

The essentially means speeding up the electric water pump.

That doesn't really explain all the failures.

Germany has yet to figure out how to make viable plastic or rubber.

The pressure cap on the cooling system establishes system pressure, not the water pump.

The most recent and just about only major change I've noticced is the t-stat now controls flow from the radiator not to the radiator.

Knurled. said:z31maniac said:aircooled said:More modern BMWs have a plethora of operating modes to meet various cooling goals. They use sophisticated electronics to control the operation of the thermostat and water pump to oversee internal engine and accessory temps.

The essentially means speeding up the electric water pump.

That doesn't really explain all the failures.Germany has yet to figure out how to make viable plastic or rubber.

I agree, for what they charge and the maintenance costs, it's not reasonable, even given how well they drive.

In reply to z31maniac :

Depends on the BMW in question. You can replace the entire cooling system (radiator, water pump, thermostat, idler pulley, hoses) for an M50 powered car for $400-450. If you are really worried about a failure you would do that every 60,000 miles. Do other cars have to deal with cooling system repairs as frequently, no, but the cost is less than $.01 per mile. Not exactly what I would call unreasonable cost, but I guess people have different ideas of what is reasonable.

Displaying 1-10 of 32 commentsView all comments on the GRM forums

You'll need to log in to post.