what forces does the mount have to react? let form follow function -- though it does look a little sketchy all cantilevered out there.

what forces does the mount have to react? let form follow function -- though it does look a little sketchy all cantilevered out there.

NOHOME wrote: I would get rid of the Z shaped mount, lengthen the crossmember to go directly under where the Z bracket is now mounted with the two bolts and use a piece of box tube to mount directly under the frame.

This is the best option so far and is likely what I'll do. The other immediate option being to add a vertical ear to the Z shaped pieces and tie it into the frame rail so I have support in two separate planes. I'll look at both options tonight.

I am not worried about the Z shaped pieces themselves failing. They are 3/16" plate and are quite stout for what I'm asking of them. I'm worried about the cantilever action pulling those 8mm studs out of the mounting points.

Adrian_Thompson wrote: You are doing awesome work like this and I can't even get my 1988 Saab running. I think I'll go and curl up in a hole and rock myself to sleep while crying in a fetal position. This is awesome, I'd love to do this too an Imp, then I remember I can't even get the Saab running again.

This part of the project is really playing to my strengths as I make my living as a Industrial Maintenance Mechanic/ Fabricator.

I am absolute rubbish at making cars run or run better (unless CIS is involved, strangely enough). There's likely going to be a point in this build where I have to call in favors from some Automotive Mechanic buddies.

That looks like a terrific workspace! What sort of building complex is this?

Whats the dogleg in the upper left of the image? Another room? How do you access the loft?

It's a rent-a-shop kinda complex. It's a little spendy, but it's all inclusive. Compressed air, 220v, WiFi, and a 60" TV with a stupidly ridiculous cable package. I am paying the same amount as I was in the old unit, but I am going in halfsies with my buddy Tyler.

There's no dogleg, just the one room. Loft access is going to be gained by an attic ladder as soon as I get around to buying and installing one.

Sweet garage condo! With a small car like an 850 you might need to get another 850 to maximize your return per square foot.

At the ones near me, you can set up the layout however you want. A lot of people have a bathroom and an office/kitchenette.

It makes me want to start doing my own business (or at least get a 100% work-from-home job) so I can make that my "office." It might be hard to run a conference call while rattle gunning off a strut bolt, but I'm confident I can work around such plebian concerns as I rise to a titan of industry while also figuring out how to work a paint gun.

They aren't 'code' for living in though, so I would guess anything more than an occasional catnap on a couch would get some raised eyebrows.

So now that you have a dedicated workspace, surely this project must be proceeding gangbusters, right?

Or has it devolved into a Laurel & Hardy slapstick frenzy of tripping over each others' air hoses and fighting over the last can of POR15?

Still getting settled in. Been busy with other aspects of life for the last two weeks, but my schedule is freeing up a bit now. Hopefully I can get the rest of my crap moved in tonight and finalize the layout of the shop a bit.

But then I have to throw a transmission in my e46 wagon, so I expect that to eat the majority of a weekend.

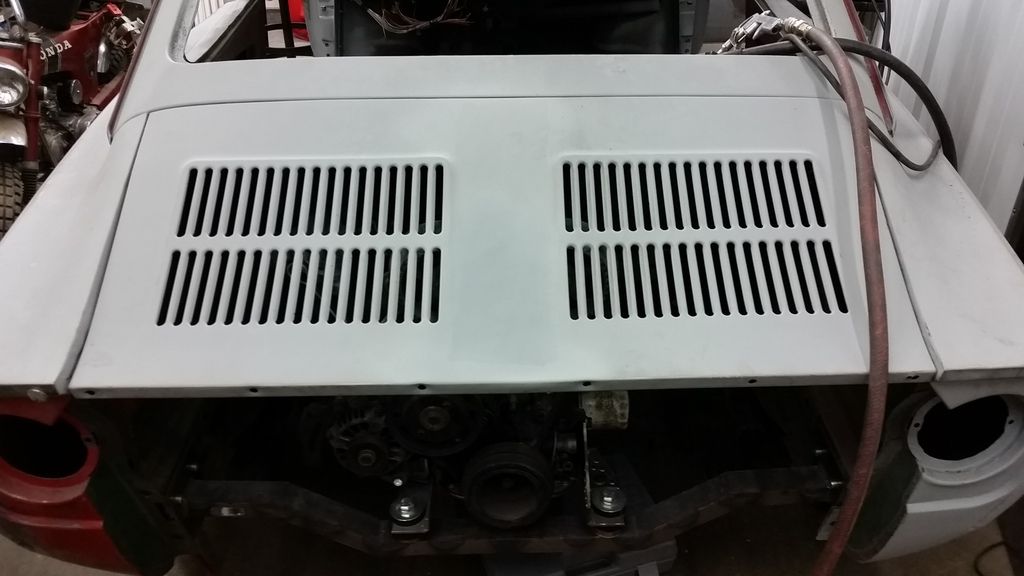

Did a couple little things on the car tonight after getting it all uncovered.

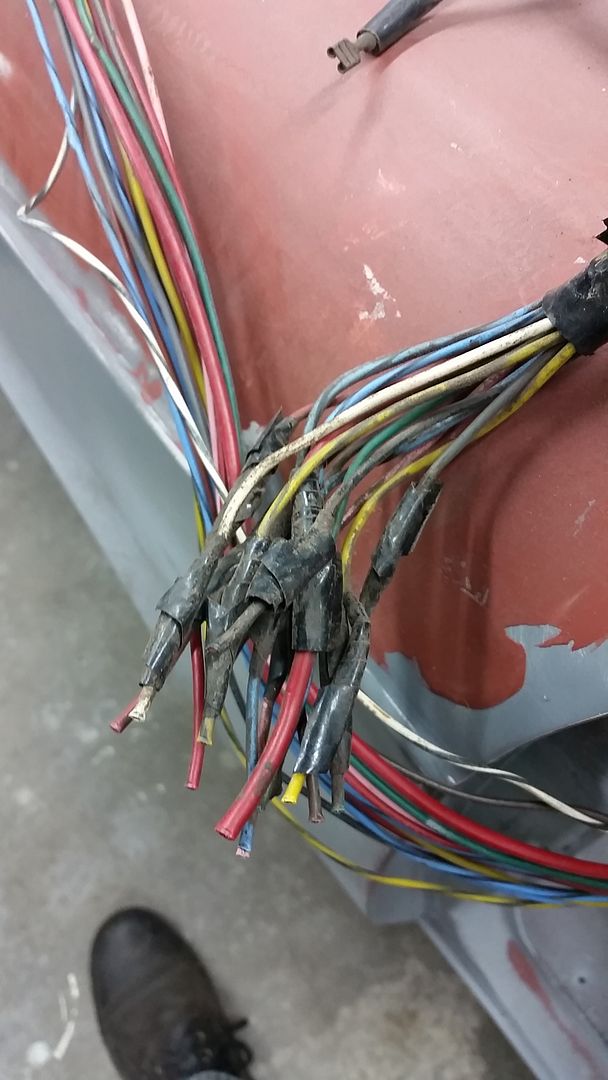

I've been tripping over the wiring harness since I started the build and decided enough was enough. Luckily it has some Auction quality splices, so I didn't feel bad about cutting it short.

Now it's all coiled up out of my way and out of reach of wayward grinders and welding slag.

Much better. Probably should have done that ages ago.

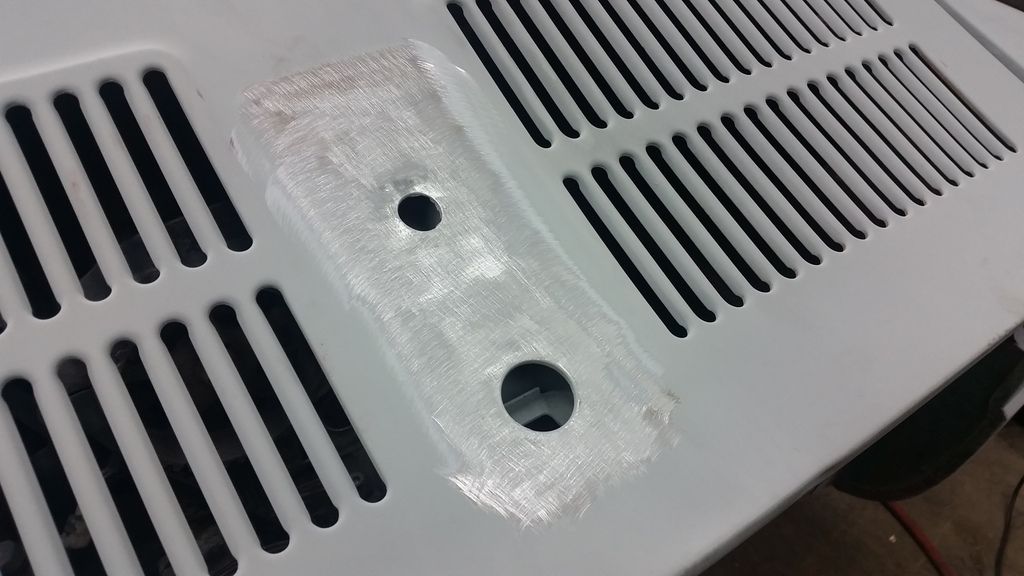

On the rear decklid there was an extra hole- well two of them since I will be running the decklid propped open I won't need the factory latching mechanism.

I honestly don't know what this hole was for. It's not factory and wasn't particularly round. After a little love from the die-grinder I had it round enough and properly sized to drop one of the 3/4" plugs from the Plug-O-Matic from a few pages back.

Let me tell you, Welders work so much better when you feed them the proper voltage through wires large enough to support their appetite for current. All of my notes about preferred settings from the last shop are worthless now. So no raw weld photos this time around; between being 2 months out of practice and having a completely different setup, you aren't missing anything. ![]()

Hopefully tomorrow I can fill in the larger hole before turning my attention to the litany of holes on the trailing edge of the decklid.

With any luck this build will return to it's 3-4 update per week schedule soon. It feels good to finally get back at it.

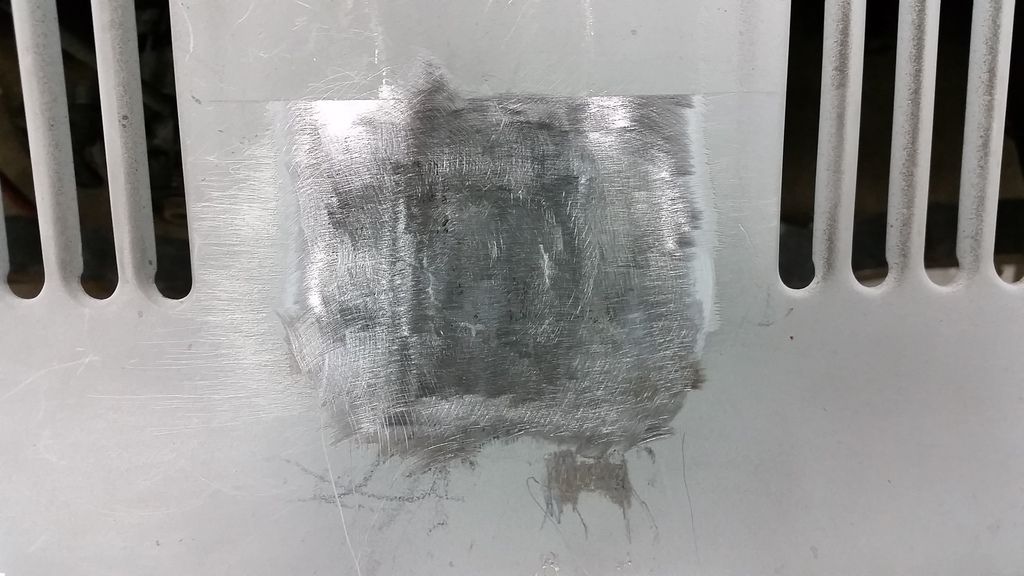

Ok, continuing on with the hole-ectomy.

This one has a little lip on the backside of the panel. This will need to be ground flush and the surrounding metal cleaned before welding.

With that done I set about making the plug. The typical masking tape template was made and cut close with tin snips.

And then after a few trips to the belt sander if slipped into its new home. I continued grinding on it a bit after this so it didn't pucker the panel when I welded on it. I also knocked a gentle curve into it to match the decklid.

Tacked.

Welded and ground back. It's not perfect, but such is life.

I think I'll be able to hide it just fine with a skim of filler.

Tonight is shop night, so maybe another small update later.

Back up and running! Nice to see it.

That wiring harness is gross, were they splicing in accessories or was that all just "gotta make it work" idiocy from POs?

Burrito, your metalwork always looks great, and I'd like to be just like you. So, the question: Does a small air gap around the patch make for less warpage in your experience? A "perfect (tight) fit warps more? Thanks for the entertainment.

wheelsmithy wrote: Burrito, your metalwork always looks great, and I'd like to be just like you. So, the question: Does a small air gap around the patch make for less warpage in your experience? A "perfect (tight) fit warps more? Thanks for the entertainment.

I will be interested in the answer also.

Warp is caused by the contraction of the liquid metal contracting in three dimensions and pulling the attached meal along with it.

If you weld in such a way that you have full penetration, the metal will be pulled evenly in all three dimensions.

If the bead is just sitting on top of the seam, it will pull in two dimensions and want to fold the two sheets together.

Leaving a gap makes it easier for some people to get full penetration using less heat, so if that is the case, its is all good.

I aim for a tight gap and weld hot to the point where the leading edge of the weld bead actually opens up a bit. I believe that the proper term for this is "Keyhole Welding". If I happen to have a small gap, not a big deal either.

Welders explanation of Keyhole Welding:

" Keyhole - When welding an open butt, or open groove weld JOINT with STICK, MIG or TIG, a "keyhole" will open up. When the sides of the plate burn away on each side of the WELD POOL a hole is formed which allows for good TIE IN and PENETRATION.

The keyhole must not be allowed to grow too large or the WELD POOL will waterfall out the back of the joint."

Remember how last week I said there would be more updates? Here's the update: The car is resplendent in her new "open air" surroundings while the E46 wagon is positively exploded in the shop.

So, probably no updates this week. ![]()

NOHOME wrote:wheelsmithy wrote: Burrito, your metalwork always looks great, and I'd like to be just like you. So, the question: Does a small air gap around the patch make for less warpage in your experience? A "perfect (tight) fit warps more? Thanks for the entertainment.I will be interested in the answer also. Warp is caused by the contraction of the liquid metal contracting in three dimensions and pulling the attached meal along with it. If you weld in such a way that you have full penetration, the metal will be pulled evenly in all three dimensions. If the bead is just sitting on top of the seam, it will pull in two dimensions and want to fold the two sheets together. Leaving a gap makes it easier for some people to get full penetration using less heat, so if that is the case, its is all good. I aim for a tight gap and weld hot to the point where the leading edge of the weld bead actually opens up a bit. I believe that the proper term for this is "Keyhole Welding". If I happen to have a small gap, not a big deal either. Welders explanation of Keyhole Welding: " Keyhole - When welding an open butt, or open groove weld JOINT with STICK, MIG or TIG, a "keyhole" will open up. When the sides of the plate burn away on each side of the WELD POOL a hole is formed which allows for good TIE IN and PENETRATION. The keyhole must not be allowed to grow too large or the WELD POOL will waterfall out the back of the joint."

This is what I was shooting for on this patch. Mostly just trying something new. There's a really great panel beating thread on RetroRides and TonyBMW (who is some sort of sheet metal Jedi) stresses that a small gap is necessary to his process.

When I shaved the antenna hole on the front fender, I made a really tight fitting patch and welded it in hot. As I slowly worked my way around the patch I could see the patch and the area surrounding it physically move up as they tried to occupy the same space.

I'm using about 3/4 of the heat and wire speed as I was on the same materials and seeing better penetration with roughly the same weld duration.

I'm no professional, though. Maybe a real panel beater will chime in.

Scottah wrote: Would you start working on this thing again already? We need updates.

Damn, I though he had!

Uhhhh, I've got some good news and I've got some good-bad news.

The good news is I can toss together a little update with what little progress I've made in the last month later tonight (maybe, don't hold me to that). The continued good news is that the E46 is back on the road with a clean bill of health and it's almost ready to find a new home.

The good-bad news is that this project is back-burnered (I don't think "burnered" is a real word...) once again. Why is this good-bad? I bought another Fiat and, as we all know, Fiats are rad.

This one is for the Bride of Burrito. It should be a pretty quick project; fix the mind-boggling small amount of rust, shave the corner markers, send it off for paint, lower it (a lot?) and refresh the suspension, and get it road worthy. Since it's essentially not mine, I won't be limited by the usual, uhhh, budgetary restraints (hence the selling of the E46).

The deal we've struck is that I'll do the work if she does the documentation, since her passion is photography and mine is rust. I'm going to do my best to do a Drivabeater/Tuna style parts break down and track real world costs. We will probably break challenge budget fairly quickly as a result of not wasting time.

This project doesn't officially start until next week. Future in-laws are here all week and a life changing event is slated for next Saturday (but I'm not supposed to talk about that on the internet, so you didn't hear it from me, ok?).

You'll need to log in to post.