Committing to Front Bars

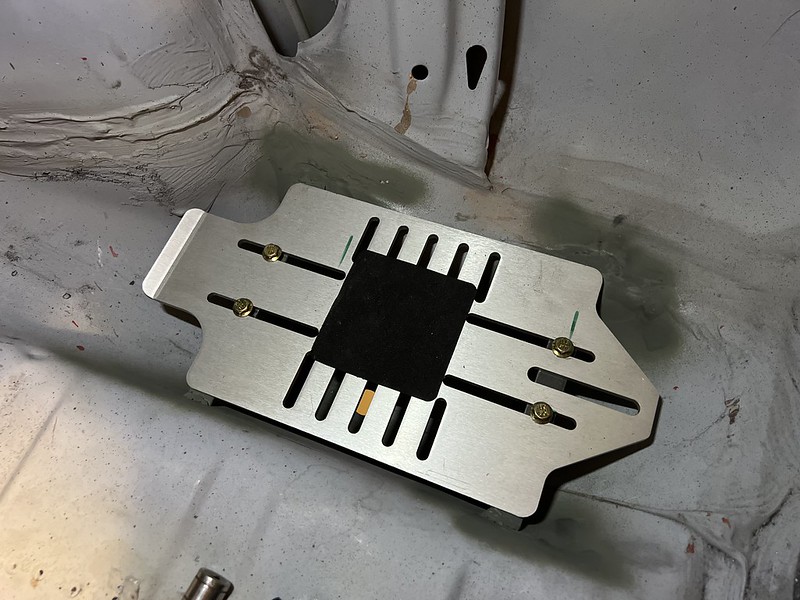

The last time we referenced the front skid plate bar was back in May when we were installing the front tow hook which is sandwiched between the chassis rail and the skid plate bar mounting flange. At that time, it was mocked up from PVC conduit. Now we felt it was time to commit it to steel and even connect it to the front bumper bar. How hard could that be?

Pretty tricky actually. We don’t have a pipe bender but have access to one but it would be a one shot deal. However, it proved difficult to make the compound bends in the same plane and end up with the bar at the correct length. When we got it back to the workshop what we had was a wrong length bar with a 90 degree bend at each end! Both bends were in the same plane but, as you will see, that didn’t matter in the end. It was a bit disappointing to be honest so we put the kettle on and had a think over some Yorkshire Tea and Hobnobs. They did the trick as by the last sip and crumb it dawned on us that we had all the right pieces, just not necessarily in the right order! If we chopped up the continuous 90 bends we could configure them in the right way and make the bar any length we wanted and we wanted it the correct length. So that’s what we did.

We even got it to “make the noise” (be level if you’re watching in black and white)

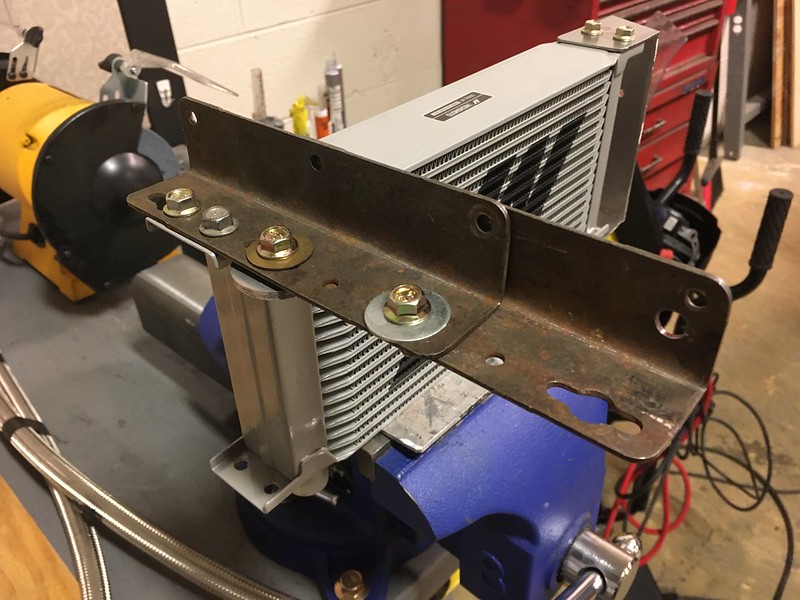

The next part of the project was to connect the skid plate bar to the bumper bar with a couple of brace bars in such a way that either bar could be removed separately. Fortunately, we had a model for this from MAT’s restoration, which we are not copying in any way shape or form, honestly.

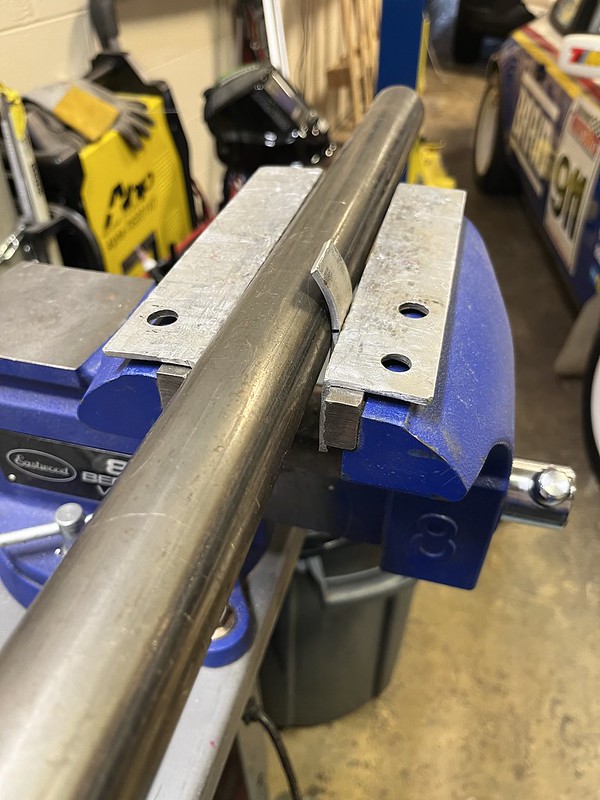

So, we squished some pipe:

It took ages to grind the correct angle on the top but once we were happy with it we tacked the braces in place with the bars in situ:

Then a few issues revealed themselves. Firstly, the right-side brace bar interferes with the intercooler inlet pipe so that will need to be modified

But also, and more fundamentally, we couldn’t remove either bar from the car! We were perplexed for a few minutes as we had the configuration just like the MAT restoration bars but then we realized we had mounted our bars with studs and nuts and they had uses bolts! Once we removed the studs from the bumper bar flanges it fell away elegantly. We will be attaching it with bolts from now on. DUH!

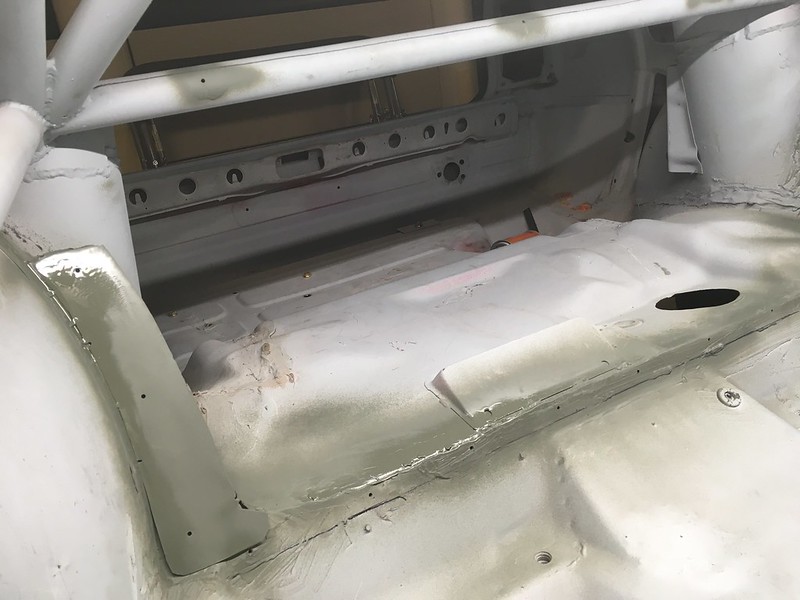

So here are the two bars tacked together and removed and primed later.

We’d like to see a Norwegian Blue muscle up to these bars and try to bend them apart with its little pecker!