Regarding root cause of the original problem, I'll cite two factors already listed: shortage of adequate oiling, and bad valve tip condition. The motor appears to be one of the bastard Mark V (or at least the heads are), cursed with all of its predecessor's issues and none of the later fixes with a sizable helping of new mid-90s GM cost-saving E36 M3 to deal with. It's true that the Big Chevy has a weakness in the valvetrain layout, but mostly just due to mass. It also requires dilligence in setup if you're at all outside the bounds from factory geometry. The design is actually very good, and a large part of why the BBC continues to be a contender in horsepower battles even today with contemporary competition.

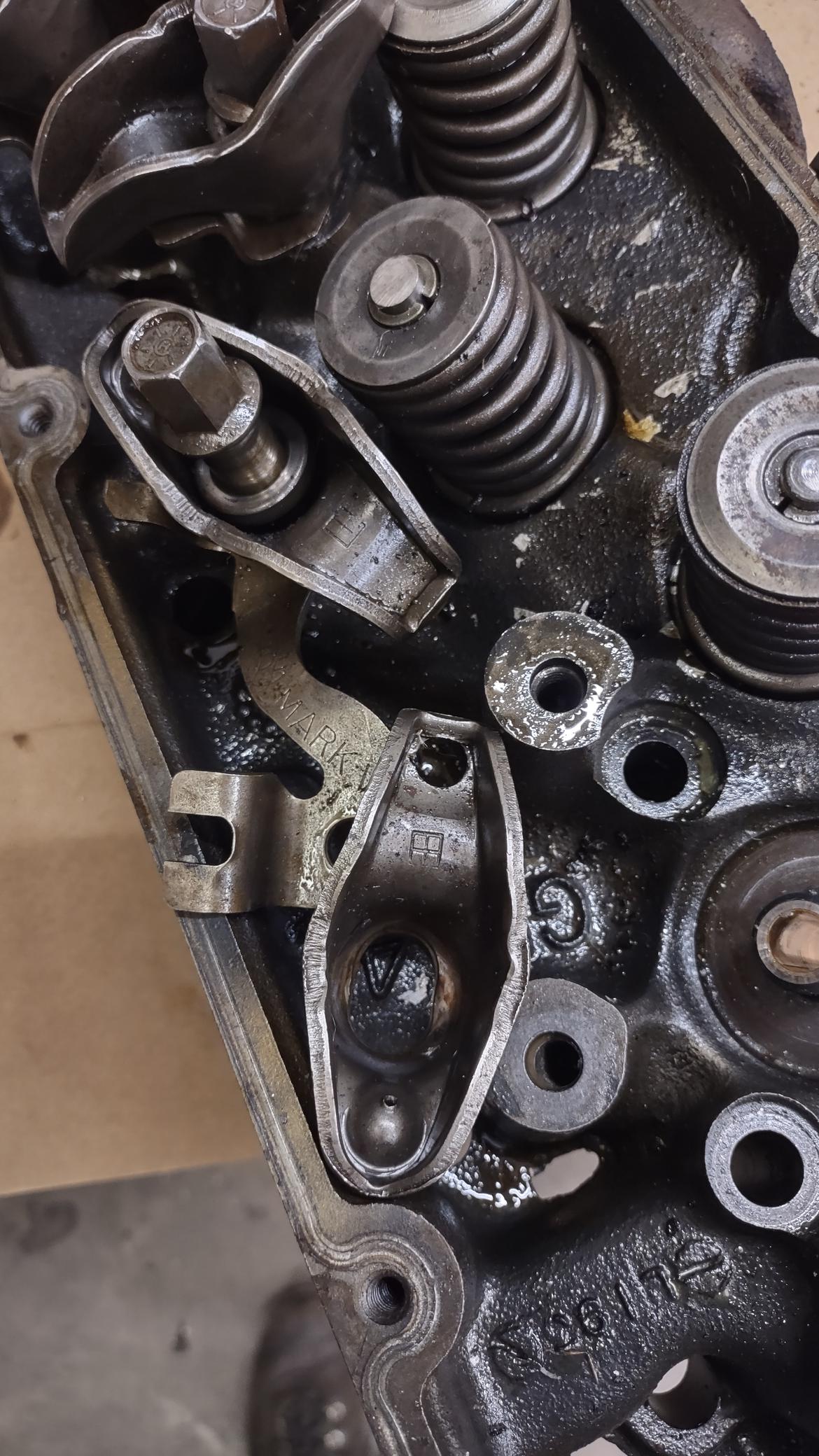

For a third: the non-adjustable Mark V rocker bolts are also a very likely conspirator. The premise requires a very specific valve tip height to establish correct lifter preload, and I'll bet that dollar-store valve job didn't get it there. The direct effect using factory-length pushrods is lifter preload, and low tip heights will result in low preload and probably some free lash. The rockers are stamped with the window symbol, which is a GM mark. Not great, but not particularly soft and terrible, so probably not the real problem. You can easily swap to studs with adjustable rocker nuts. Aftermarket roller rockers are widely available. I run steel-bodied Comp Pro Magnum rollers lifters on all of my BBCs.

The valve tips look terrible. Even in the marginal cell phone photos I can see they're not true and very coarse, although maybe flat. The factory valves have hardened tips, and if dressed correctly should last the life of the engine. If dressed improperly and not perfectly aligned to rocker plane, they will become an angry hardened rotary file and easily chew through even an adequate stamped rocker. Remember they rotate. Roller rockers will show uneven witness marks on the tip roller in the same scenario. You might also have some bent rocker bolts.

The springs appear to be completely stock and completely adequate, but should be measured for seat and open pressure. I'd be taking a real hard look at the one that punched through for retainer or lock damage since that was what the business end of the rocker was pounding on.

Asphalt is correct about the sodium-filled exhaust valves, as well as the suitability of a quality aftermarket stainless replacement, but they also have an oversize 3/8 stem which can be hard to source a replacement for. Good stock valves are the easier option.

I would also be inclined to check out the oil pump. GM only put minimal effort into the oiling on BBCs. The short block will survive a surprisingly long time with poor oiling, but the valvetrain won't. If the pump is in good shape and makes at least 50 psi before bypass, it should be OK. Use a priming tool to verify, and make damn sure you're getting oil thru all 16 pushrods. If you do put a pump on it, don't use a high-volume unit, just increased pressure. If the standard volume pump isn't enough, the motor has an internal leak.

Check out all 16 cam lobes 360 degrees with bright light and the help of an assistant to slowly turn the crank. Easy to see thru the drain-back slots in the valley. Be absolutely sure you're not putting effort, money, and new lifters on a cam with a bad lobe. It's very common. I have refused to built flat-tappet motors since the 90s because I'm tired of lifter mysteries.

If it was mine, the heads come off and get completely gone thru no question. Also not much faith in a short block built by the same shop as the heads.