wae

PowerDork

1/14/23 2:02 p.m.

All cleaned up.

And the valve train reinstalled. I even remembered to put all the valve stem seals in place before installing each spring! That's a new milestone for me.

Hopefully tomorrow evening I can at least get things all ready to drop the head back on. I should have a oil pump priming tool arriving today as well. Which reminds me... I'll probably want to get some oil and coolant as well.

wae

PowerDork

1/19/23 6:34 p.m.

Well, crapola.

Since the weather is turning cold and nasty, I wanted to get the exhaust reconnected, the oil drained, and a new filter put on. After draining the pan, I kicked the container out into the sunlight and the bit of oil that was left on top of the drain pan was glittery. I cleaned things off a bit and poured the contents of the oil filter out into the sun and it, too, had plenty of glitter. The oil I sampled before wasn't glittery and I've opened up a couple of the lifters and that oil isn't glittery either. I'm going to cut the filter open and take a look, but I'm concerned that there's more going on here.

In reply to wae :

All used oil is glittery to some extent. And you KNOW there was metal floating around in the oil because you had a major valvetrain failure.

If it wasn't smoking, you don't have metal embedded in the piston skirts honing the bores while-u-drive, if it had good oil pressure then you're fine.

wae

PowerDork

1/21/23 10:53 p.m.

In reply to Pete. (l33t FS) :

Yeah, no smoke and the dash gauge was showing pressure, although I don't necessarily trust its accuracy completely. Other than the ticking, there were no funny noises and it really ran just fine.

I poured the zinc break in stuff all over the cam and filled it with oil. Used my drill to prime it and got oil out of most of the pushrods - I didn't rotate the engine at all yet. Using a mechanical gauge, I'm getting about 32psi on my 950rpm drill which should translate to 1,900rpm. I was kind of hoping for more like 50psi or so, what with everything being a bit cold, though.

That's not a lot of oil pressure. What oil weight are you using? The cold should make for even more pressure. Hopefully it's just air working out of the system.

Do I see sunk exhaust valve seats in the head photo? How did the tip heights measure out?

wae

PowerDork

1/22/23 8:46 p.m.

Yeah, I was hoping for a bit more. I've heard tales of cheap priming tools not sealing right on BBCs, so I'm going to put my inspection camera down the drainback and see if there's oil coming out from around that bushing. The oil is 10-30 and was at about 70 degrees.

Having nothing to compare it against, the seats didn't look sunken. At a bare minimum, they all looked the same compared to each other. I don't have the measurements, but the valves were of varying height in a range of around an eighth I think. Could have been a little bit closer than that. I left the two exhaust valves that were still very nearly the length of a new one and replaced all the others on that head.

I highly doubt your drill was turning 950rpm while turning an oil pump unless you had a giant corded electric one with two grab handles. It takes a LOT of power to turn a pump.

My air drill turns at about 100-120rpm when priming an engine. It's much faster when unloaded :)

wae

PowerDork

1/22/23 9:46 p.m.

I was using my corded drill and it's nothing special, but it was pretty well wound-out. It was certainly taking less effort for me to hold it than when I used it to mix thinset....

wae

PowerDork

1/24/23 8:09 a.m.

I took a quick minute last night to verify that there is no oil coming from around the bushing on the priming tool, so the tool is properly machined. Even after rotating the engine roughly 90 degrees, I'm still at that same 32psi. Paying more attention to it, it does drag the drill down a bit and require a decent amount of torque to keep it from spinning the whole drill. The rest of the internet, however, seems to be able to get to 50 using a corded drill, so there's certainly something different here. I also really don't have any idea what the oil pressure was, historically. There's a gauge on the dash but I don't really remember where the needle usually sat - just that it looked "fine" and never dropped to a level that my brain would have freaked out about, including on the trip back from Florida last time with it ticking away.

At this point the worst-case scenario of firing it up and breaking in the lifters is that oil pressure will be catastrophically low and I'll need to tear it down. Alternately, I could tear it down anyway and freshen up the bearings, put in a new cam, send the crank to the machine shop, and all that jazz. The only thing I really have to lose by doing the lifter break in to check and see is that I'd have to throw away my brand-new lifters and they're only about $6-$7 each.

So my plan is to wait until I get back and go ahead and finish putting it back together, get it timed, keep the manual gauge on, and do the cam (lifter) break-in and see what happens.

I'd personally fire it. I am quite sure it will be ok.

wae

PowerDork

1/24/23 9:48 a.m.

In reply to Professor_Brap (Forum Supporter) :

If my plan wasn't to immediately drive 2000 miles towing a car, I probably would have already done that! I think some "around-town" driving before I hit the open road might be a good idea.

wae

PowerDork

12/18/23 9:14 p.m.

Hey, yeah, so coming back to this....

Since I never do anything if it's not the last minute, I'm finally trying to wrap this up. I've just got to get the timing set and I'm ready to fire it up and break in the new lifters.

I understand that I'm supposed to fire it up and immediately take it to 2500 RPM and hold it around there for 10-15 minutes. But what happens if something happens? Let's say one of the belts isn't right enough or it's leaking something because I didn't tighten something. Have I created a huge problem by shutting it down mid-break-in and then firing it back up to finish?

No, it shouldn't cause any problems. I've had to stop break in for leaks or loose hardware, never caused any cam and lifter issues. Just continue the break in next start.

Yep just shut down, fix it, and continue.

wae

PowerDork

12/18/23 11:44 p.m.

Cool, thanks! Fingers crossed!

wae

PowerDork

12/19/23 2:12 p.m.

Well, all buttoned up (probably) and ready to fire it up, but the batteries are so flat even the jumpbox won't work. Doh!

wae

PowerDork

12/20/23 12:16 a.m.

So, some good news: I put a new battery on it and I get about 40psi of oil pressure while cranking - better than what the drill could do.

The bad news, though, is that I can't get it to start. I've got fuel and spark. I can't get a timing light on it from the top because motorhome - The visible timing gauge is on the underside for the #5 wire, but it's pretty hard to get to the ignition switch from down there. I tried rotating the distributor cap a few degrees each way to no avail. I pulled the fan off again, rotated the engine to get the TDC mark to the 4 degree mark on the top gauge (which is for cylinder 1, I'm assuming), popped the #1 spark plug out again and put my camera in there to verify that both valves were closed, pulled the distributor off again, reset it so that the rotor pointed to #1, put the plug wires back on in 1-8-4-3-6-5-7-2 order. Still no dice.

It kind of pops a little when it's cranking and if I hold the throttle down, it coughs pretty loudly - but it's more of a backfire sound than a I'm-trying-to-start cough. Am I missing anything on setting the timing? I've checked, double-checked, and triple-checked that the #1 cylinder had both valves closed at TDC. Same thing with the plug wires to verify their order. The wires are on the cap in what I am assuming is the correct firing order in a clockwise direction. The throttle body has plenty of fuel vapor in it and the #1 plug was fairly wet after cranking, so fuel is getting up there. I put my spark tester on a plug wire and it gives me good spark. I replaced all the lifters, all the pushrods, a rocker arm on the right side, and all the valves on the right side. I haven't taken the valve covers back off to look, but I really thought I had everything together in there and the valves were all opening.

What am I missing here?

ShawnG

MegaDork

12/20/23 12:27 a.m.

If it has the flat cap with the wires coming out the sides, the firing order on the cap is different from the firing order on the old, round cap.

All the wires for the left side of the engine come off the left side of the cap, right off the right side.

wae

PowerDork

12/20/23 6:41 a.m.

In reply to ShawnG :

While I can't be absolutely sure that the firing order now is the same as it was before I started berkeleying around with it, the wires do still have the same basic even-side/odd-side pattern that it had before as they go around the cap. Not thinking that I'd have to pull the head, I just labeled the wires sequentially as they go around the cap and then the sharpie has faded quite a bit over time.

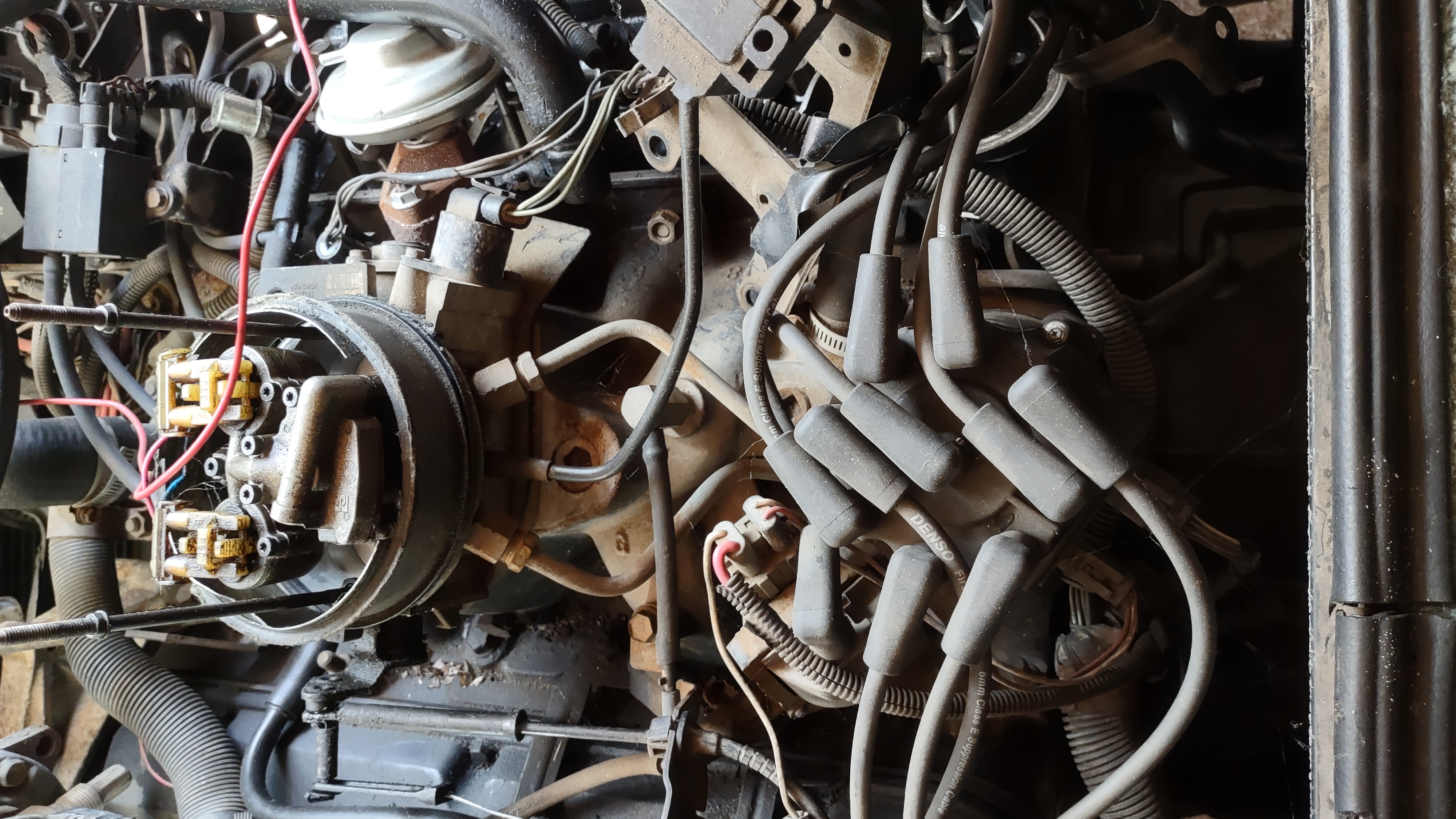

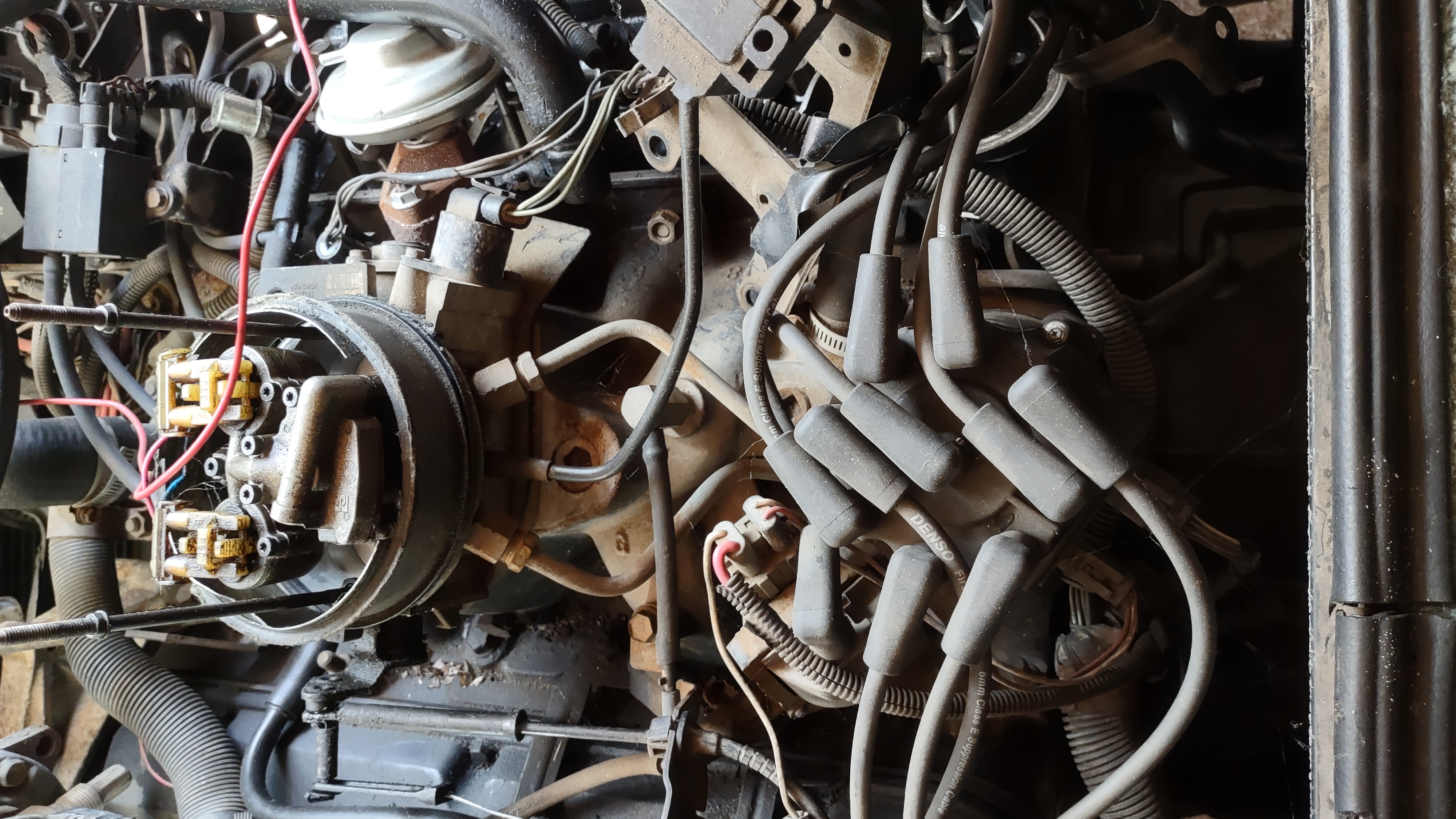

This is the "before" view:

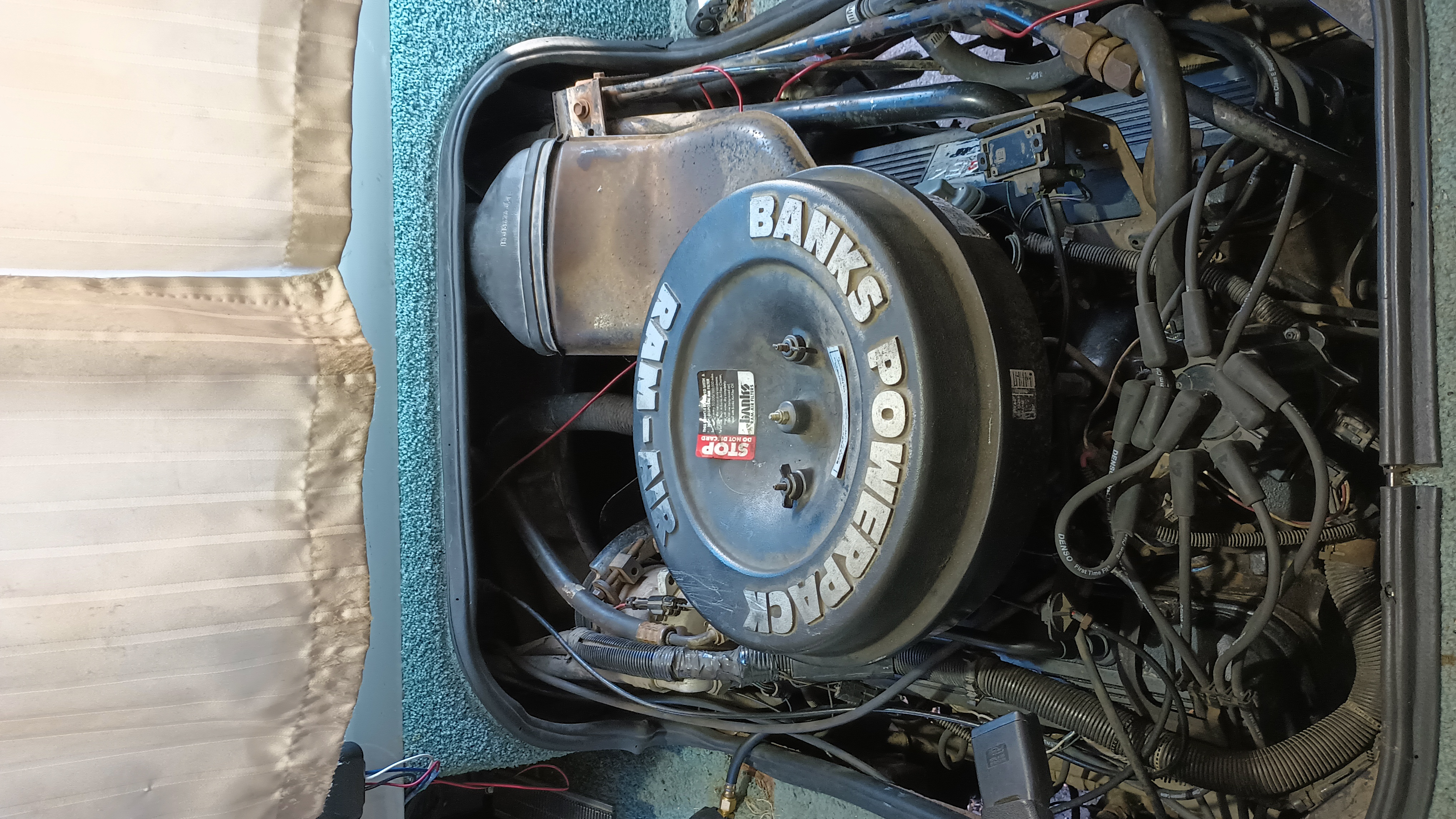

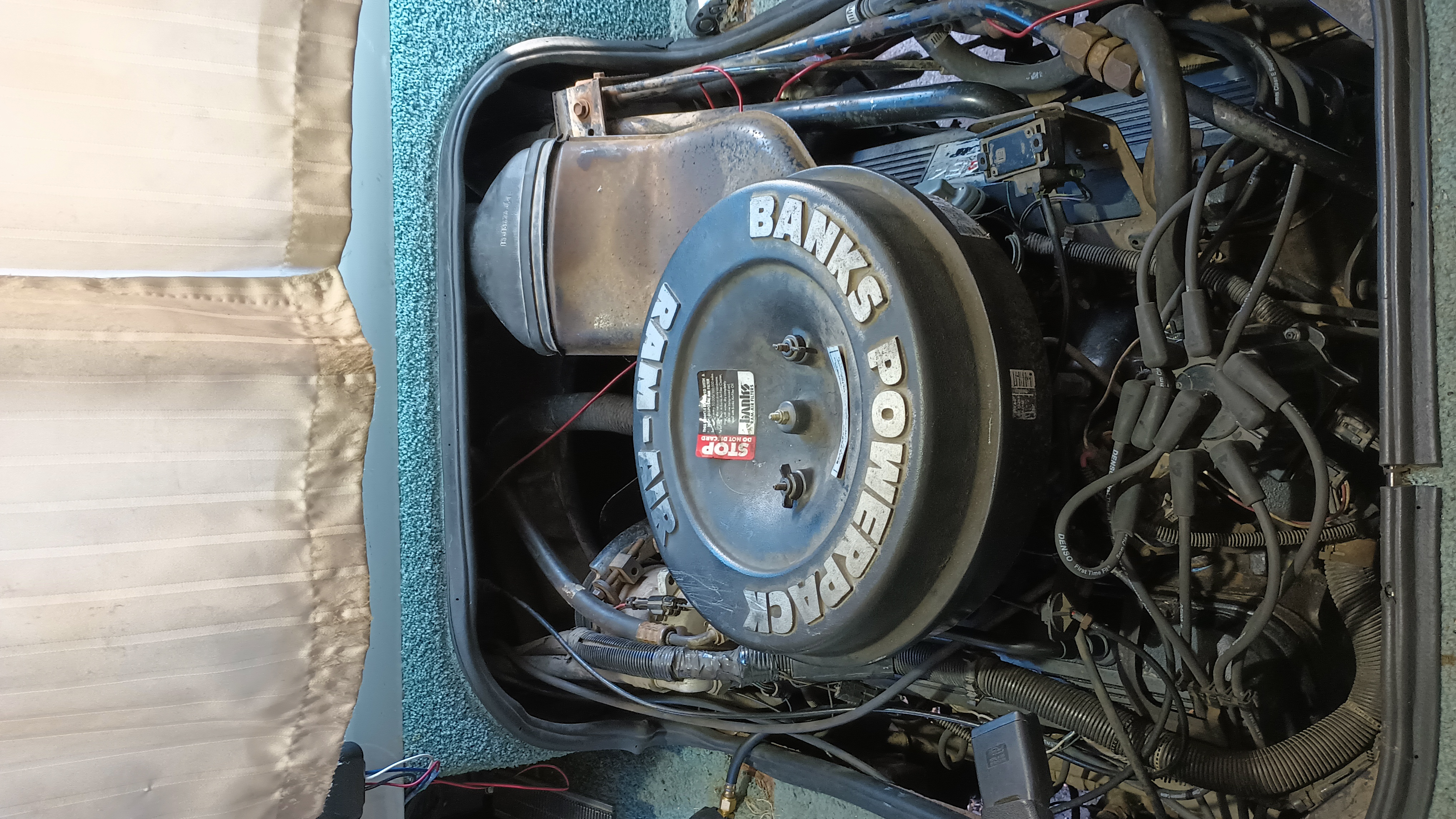

And after:

I would check to see if the distributor is 180 off, because that sounds like what happens. An easy check is rotate all the plug wires around 4 spaces on the cap. 1-6, 8-5, etc. as many chevy engines as I have assembled, I still put the distributor 180 out in the wartburg. It was popping and farting and sounding like it may do something and backfiring out the carb a bit

wae

PowerDork

12/20/23 7:49 a.m.

In reply to Patrick :

I'm down for giving that a try. That was my first thought, actually, but rather than just swapping the wires around, I stuck my camera down the plug hole and verified that both valves were closed, the piston was at the top of the cylinder, and the rotor button was lined up with the post that plug #1 was connected to.

That said, I'll flip the wires around and see what happens. Because it does kind of have that sound of an engine that's 180 degrees out.

Classic symptoms of 180 out. The tiny camshaft and hydraulic lifter bleed down are fooling you into thinking you have the right TDC. I'm not doubting that the valves are both closed, but it's likely still the wrong TDC. That's the small-cap HEI but still uses the same sequential firing order as the big cap.

Chevys are easy. Find TDC compression number 1, point the distributor rotor at #1 cylinder, align the reluctor with the pickup

wae

PowerDork

12/21/23 6:24 p.m.

Okay... I flipped the plug wires around and then with a tiny twist of the distributor, it started up. It's trying to bounce the distributor up and out of its hole, though, so I need to figure out how to get around the fuel lines to the hold down bolt.

Here's my question, though: how the berkeley did I have that wrong? My first thought was that it was 180 out, but both valves were closed in #1. Apparently there is more to it than what I thought, so please learn me.