Mickey Thompson used articulated pushrods in his Ford 427 Hemi:

Would you be able to get a reasonable measure on the max combustion chamber depth, and the general casting thickness of the combustion chamber itself?... Inquiring minds, and whatnot.

In reply to Driven5 :

Probably. I'm not sure I have those type of calipers hanging out, though. I'll check what's in my tech drawer.

I did find a decent solid model of an LS head that I can use for design, so I won't need to cut up those end pieces. If you want to PM me your address I can mail them off to you.

Message sent.

Also glad to see such good results with the high-temp solder (low-temp braze?) rods. I see you went with the 'recommended' Hobart product. Were they as easy to use as the video made them look?

In reply to Driven5 :

I don't see the message yet, not even in the Spam folder. I usually get them just fine. Strange. I'll message you in the morning if I don't have it

Technically high temp solder, I believe. Below the temp for brazing. Overall I think they were well represented in the video. A few things weren't really covered in it, but that's just because it was more a comparison vid than a how-to dive. I put a thread in the Tech Tips section based on my thoughts.

So much fun! Lovin’ it.

I know it’s fun moving fwd. and all, but is it really wise to be fitting parts to a head that isn’t welded yet? I see potential for a problem in the future there?

Maybe a crazy thought, but perhaps instead of trying to weld the heads together, plate off the ends of the passages and then use some high-temp o-rings to connect them?

03Panther said:So much fun! Lovin’ it.

I know it’s fun moving fwd. and all, but is it really wise to be fitting parts to a head that isn’t welded yet? I see potential for a problem in the future there?

Oh, 100% possibility that I'm berkeleying up. However the solder is as easy to remove as it is to apply, and I could always just cut it again.

Ian F (Forum Supporter) said:Maybe a crazy thought, but perhaps instead of trying to weld the heads together, plate off the ends of the passages and then use some high-temp o-rings to connect them?

I'd be concerned I'd end up with a restriction in coolant flow.

ShawnG said:Mickey Thompson used articulated pushrods in his Ford 427 Hemi:

That doesn't make it any less ugly!

In reply to californiamilleghia :

Hrm. Possibly, they'd be fairly small dowels though. Outside of the combustion chamber areas the widest point in these is about 1/4"

Not every day is filled with awesomeness, sometimes its just the hum drum methodology of making sure you don't look like an shiny happy person when you're done.

Wanted to check the head gasket and see if there were any glaring issues. I don't think there are, but I don't 100% like it. The locating dowels are going to need to be worked on at some point, I think.

Took the valves out so I could take the parts to my machine shop and have them clean everything in preparation for welding. The LS style valve compressor is so much nicer than my truck's, easily took a quarter of the time.

BTW - are the LS intake/exhaust springs and spring retainers interchangeable? With the compressor they seemed to compress evenly as I squeezed them.

Mr_Asa said:BTW - are the LS intake/exhaust springs and spring retainers interchangeable? With the compressor they seemed to compress evenly as I squeezed them.

Yes, they're the same parts.

So what's the plan for that DMZ between the 300 headgasket and the edge of the head where the green bar is currently bolted? I assume those open volumes normally pass coolant around the ports?

In reply to pres589 (djronnebaum) :

Nope. There are two areas right on the ends where it looks like on the LS there's some sort of coolant crossover, but for the most part it is open and is the oil drainage area for the valvetrain. I'm going to have to make some weird lifter cover that meshes the 300 block and LS head, you can sort of guess what it will look like if you look at the pictures in the early part of the thread.

Anyone have any idea about what HP numbers engine will pump out if I leave the stock camshaft in with the new head? A new cam may be a possibility, but right now I'm aiming for as little money into it as possible in preparation for a challenge build.

I'm mainly looking so I can start sizing injectors and other factors so I'm able to start hunting in the junkyard.

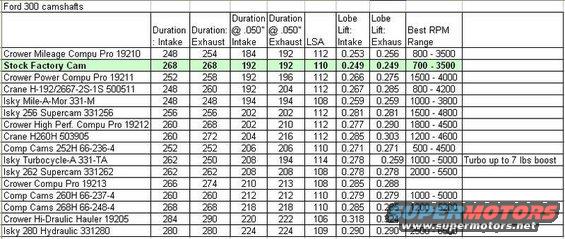

I found this for the stock camshaft, and it seems to gel with other pages I've seen

Here's info on flow numbers:

Casting Number 706 and 862

Head: 1999+ 4.8L / 5.3 Liter Truck

Material: Aluminimum

Part Number:

12559862

12561706

Combustion Chamber Volume: 61.15cc

Compression Ratio: 9.5:1

Intake Port Volume: 200cc

Exhaust Port Volume: 70cc

Intake Valve Diameter: 1.89 inches

Exhaust Valve Diameter: 1.55 inches

Stock Head Flow Numbers

Chamber 61.15 cc----0.100--0.200--0.300-- 0.400--0.500---0.550---0.600

Intake 200 cc----------63 ---128----179-----210----218----221-----226

Exhaust 70 cc----------54 -- 93 ----121----145-----163----168----174

What you need to know:

These small combustion chamber truck heads offer no advantage over an LS1 head except the smaller combustion chamber. This along with milling of the deck surface will allow a slightly higher compression ratio to be achieved. Because of the smaller intake valve installed in these heads a valve upgrade is practically mandatory.

A note on the last paragraph. The stock Ford 4.9L intake valve is 1.60" IIRC, and the max the EFI head can go up to is 1.90" or so, so I'm not that worried about increasing size.

Also, a note on roller cams so I don't lose it. I know the Nelsons were interested in this as well:

lifters

hydralic- 8931-16 (set of 16)

solid- 838-1 or 890c-1 single

linkbars(work with both solid or hydraulic)

836-L

older heads have pill shaped holes for pushrods newer heads do not if you have newer heads then you need rod guides

4839-8 (for 3/8 pushrods) or 4835-8 (for 5/16 pushrods)

timing gears

3224

distributor gear(from comp)

466

when you order your cam you can get/need

roller rockers(1.6 or 1.7 ratio)

rocker studs in (3/8 or 7/16)

beehive springs retainers and locks

pushrods either 3/8 or 5/16 (probably best to wait till assembly to check geometry before ordering)

the bosses for the side cover need to be machined approximately 1/4 inch to accommodate lifter installation the bosses at cylinder 1 and 6 need to be further machined to allow for link bar travel

if installing higher rate springs (recomended to compensate for the accelerated lift) the factory pressed in studs should be replaced with screw in type

https://fordsix.com/threads/roller-cams-for-300-big-six-thread.73706/

what are the flow numbers on the stock head? If using stock cam, I'd look at flow gain % at an average lift number and use that % to go from stock HP to LS head HP.

Very rough but at least gets you in the ballpark for injector size.

Also what is the rocker ratio before and after? 1.6-1.7? You might want to take that into account if the LS uses a different ratio than stock ford (and it's an easy way to make that small cam a bit bigger on a budget).

Like the chart below, with an average of 36% intake and 16% exhaust, or different numbers?

Stock, I think is 1.6, but may be 1.5. Let me dig. Edit: stock is 1.6

Stock head from here

Casting # E7TE-DC

From an 87 300

Lift------Intake-----Exhaust

.05-------31.8

.10-------58.0-------50.7

.15-------75.6

.20-------95.3-------80.8

.25-------107.1

.30-------119.0------108.3

.35-------131.1

.40-------139.8------123.0

.45-------150.2

.50-------157.9------135.0

.55-------162.1

.60-------166.3------140.7

You'll need to log in to post.