My MG project has reached the point where I am embarking into the great unknown of fabricating by hand nearly 12" wide fender flares (who makes cars this narrow that a stock 2nd gen Rx-7 track is nearly 2' wider than stock?)

A few warnings. These are still very much in progress. This isn't a thread where I'm going to wow you with a completed project and show you how I did it. I'll update this as I go along and really hope to be able to show you completed flares soon. Also, I've never done anything like this before so this thread might be worldwide documentation enabling people to witness Epic Fail as my flares crash and burn from a promising concept to a sad tortured reality (I hope not.. But it's possible).

So if you willing to witness the mayham and put up with some potentially slow progress, follow along!

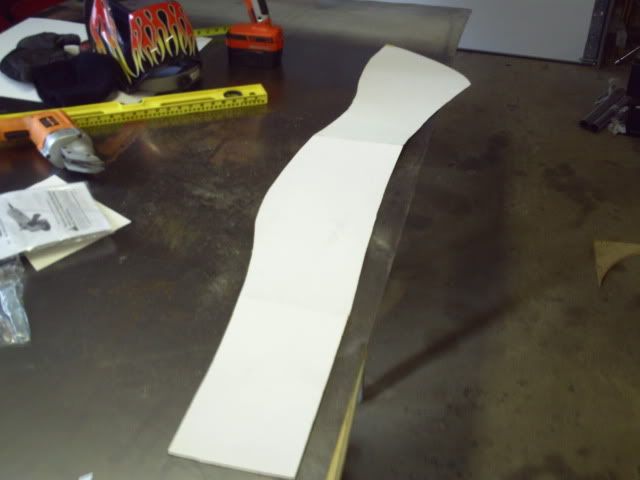

First off a while ago I mocked everything up in posterboard. I don't have the skills or equipment to truly form metal so my idea is to build flares that don't require any metal shrinking or stretching. Posterboard doesn't stretch well so If I can build something that looks good with posterboard I should be able to duplicate it in metal (I hope). This is the concept I came up with.

So now I have the body fixed relative to the chassis. I set the wheels on jackstands at ride height. I used a piece of half inch thick MDF to make a template of what I wanted the outer vertical part to look like. I laid the tire on the ground on top of the piece and traced the tire, them moved it down 2" (intended suspension travel) and retraced. I added about 1.5" in front of the tire free-form to give it some room to move. At the bottom I put a piece of 1/4" plywood so I could position it against the tire. I placed it on the tire and used an angle finder to set the board vertical and then clamped it in place.

I was then able to build a template. I unfortunately didn't have a camera when I was making the template so I will take better pictures of construction of the rear tire template. Basically I Laid poster board against the MDF in a cone shape to match the desired contour of the fender. I then slowly shaped the fender side of the template to match the profile as it hit the body. I taped the template to the body and then just used a razorblade to cut along the MDF form.

I was then able to build a template. I unfortunately didn't have a camera when I was making the template so I will take better pictures of construction of the rear tire template. Basically I Laid poster board against the MDF in a cone shape to match the desired contour of the fender. I then slowly shaped the fender side of the template to match the profile as it hit the body. I taped the template to the body and then just used a razorblade to cut along the MDF form.

I then used a Harbor freight swivel head shear to cut out the traced pattern out of 18ga steel. (great tool, use a little cutting oil and it cuts the metal like the butter)

I took the steel back to the car and then slowly worked bends into the metal. I simply bent it over my thigh.

If your template and cutting are acurate enough the part will simply fall into place and tell you where and how you need to bend it by being tight to the fender. At this point I simply tack welded it on in spots every 6" or so. I then ran out of welding wire.

I then used a Harbor freight swivel head shear to cut out the traced pattern out of 18ga steel. (great tool, use a little cutting oil and it cuts the metal like the butter)

I took the steel back to the car and then slowly worked bends into the metal. I simply bent it over my thigh.

If your template and cutting are acurate enough the part will simply fall into place and tell you where and how you need to bend it by being tight to the fender. At this point I simply tack welded it on in spots every 6" or so. I then ran out of welding wire.

The view from the drivers seat!

So that is where I am at today. I will post progress as I go along. Sorry about the low quality pictures I will try to get better ones with my other camera.

Thanks for looking!

Thanks for looking!

Daniel