The benefits of turnkey EFI sound so good that we can no longer resist the temptation.

When we first built this engine back in 2001, electronic fuel injection was widely available. It was also somewhat feared. The technology worked well enough, but you usually needed to fly in a tuning expert to properly calibrate the system. In fact, we did just that a couple of times, but always using someone else’s money.

For that reason alone, this Camaro made do with a carburetor—a custom-calibrated, hand-blueprinted Holley HP750. It worked beautifully for many years. Every circuit was individually optimized for our application. It cost about $900 back in 2001, so you can imagine how much hand labor and expertise went into that unit.

Times sure have changed in 10 years. Current aftermarket electronic fuel injection offerings claim to literally calibrate themselves. We’re cautiously waiting to confirm this claim. We’re also optimistic. The benefits of turnkey electronic fuel injection sound so good that we can no longer resist the temptation.

As good as it was, that hand-built carburetor would sometimes starve under very hard braking. It would also need to be “goosed” for a little extra “injection” from the accelerator pumps just before standing starts. Lastly, when the car migrated from the northeast to Daytona (where humidity is high), the custom calibration needed revisiting. That’s not a big deal, but along with the ensuing engine rebuild, the stars aligned for a switch to EFI.

The carburetor’s air bleeds, accelerator pumps, idle mixture screws and booster venturi are to be replaced with MAP, TPS and oxygen sensors. Though our chokeless race carburetor never really gave us trouble during cold starts, we will no doubt appreciate the benefits of an IAC-controlled engine and coolant temp sensor along with separate startup and cold start enrichment subprograms.

Of course, with current fuel prices, we hope to increase gas mileage at least 20 percent from 15 mpg on the highway to 20 mpg overall. We have all fingers and toes crossed for 22 mpg on the highway.

The switch to EFI also allowed us to make some hard changes to hard parts. EFI will tolerate more camshaft duration as it’s less reliant on “signal”—also known as vacuum. An unrestricted, straight-bore throttle body allows more air to enter the engine than a tapered venturi/booster venturi carburetor design. The extra gulp of air allows us to run smaller, more road race-friendly intake valves in our new Dart cylinder heads—from 2.055-inch diameter to 2.020-inch diameter.

Installation of the Holley HP EFI has been relatively straightforward. There is no need to wear out your Ph.D.

We also know that some of you prefer to rig your own EFI systems from scratch. That’s okay also, as most of the bits and pieces are available individually from Holley. They’re good like that.

For this car, however, it’s better to have faith in the experts. We opened the box and found properly sized injectors, the correct MAP and O2 sensors, and a fully engineered throttle body with built-in IAC and other provisions. There are some ancillary connections that you may or may not need. Make those decisions early to avoid confusion and simplify harness routing.

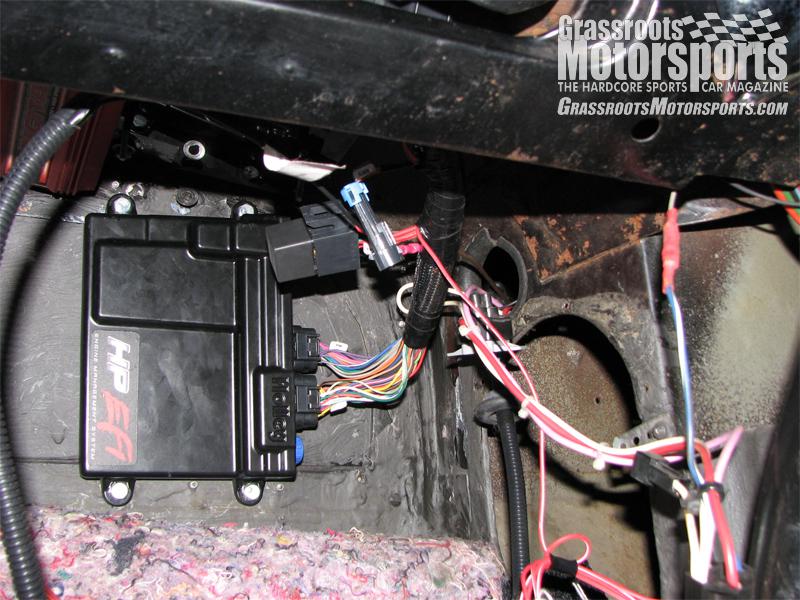

As for the HP ECM, there are myriad features including a variety of ignition triggering options, peak and hold injector drivers, and other nerd perks which are detailed on the holleyefi.com website. One of our favorite features is that this ECM can be kept when we switch over to turbo LS power next year.

For now, we hope to load a reasonably accurate base calibration to suit our high-duration camshaft. Likewise we intend to reserve time on a chassis dyno for fine tuning and analysis.

As this is a fresh rebuild, we were a bit concerned about errant calibration issues interfering with proper engine break-in. We would hate to kill our engine’s all-important ring seal by washing down our cylinder walls with fuel. We’re even less interested in blowing a hole through a piston as a result of a lean condition. When it is time to turn that key for the first time, a plan will be in place that will include a quick call to Holley‘s excellent tech support department.

We’ve also thrown our own variable into the mix by ditching the kit’s external mount fuel pump and return style regulator. We’re substituting an in-tank returnless fifth-gen Camaro fuel pump and remote fuel pickup system from VaporWorx along with a custom fuel tank from II Much Fabrication.

The new returnless pump system is a critical part of our track day transformation. The immersed pump stays nice and cool, while the VaporWorx “outrigger” style pickups all but eliminate starvation on the road course and at the autocross. It also eliminates half of the typical fuel system plumbing.

Expect a comprehensive look at this system in the next update. In the meantime, we’ve wrapped up the Holley HP EFI wiring and hard mounting. That’s a giant leap forward for this project—finally.

| To get the full story behind all of our project cars, sign up for a subscription to Grassroots Motorsports. |

| To see more of our 1968 Camaro project, click here.

|

View all comments on the GRM forums

You'll need to log in to post.